Laser cutting has revolutionised the way we work with plastics, offering high precision, speed, and versatility. Among the wide array of plastics available, three stand out for their exceptional performance when laser cut: PETG (Polyethylene Terephthalate Glycol), Polycarbonate (PC), and Acrylic (PMMA). Each of these materials brings its own unique strengths to the table, making them ideal for specific applications. In this article, we will explore why PETG, Polycarbonate, and Acrylic are considered the best materials for laser cutting plastic.

PETG Innovation

PETG is a highly durable, flexible, and versatile plastic that has become increasingly popular in laser cutting applications. It is a modified version of PET (Polyethylene Terephthalate) with added glycol to prevent crystallisation and brittleness during the heating process. This makes it particularly well-suited for laser cutting, as it allows for smoother edges and less post-processing.

One of the key benefits of PETG is its excellent impact resistance and clarity, making it ideal for protective covers, signage, and packaging. It also has good chemical resistance, which extends its use to medical and food-safe applications. Laser cutting PETG results in clean edges with minimal scorching, provided the correct settings are applied.

Additionally, PETG is a cost-effective choice compared to other engineering plastics. Its ease of fabrication and high durability make it perfect for both prototyping and end-use products. The material’s low melting point means that it requires less laser power to achieve precision cuts, reducing energy costs and processing time.

Polycarbonate Excellence

Polycarbonate is renowned for its strength and durability, often being compared to acrylic in terms of transparency but offering far greater impact resistance. This material is widely used in applications that require high resilience, such as machine guards, electronic enclosures, and protective barriers.

Laser cutting polycarbonate can be challenging due to its low melting point and tendency to discolour when exposed to excessive heat. However, with the right laser settings, polycarbonate can be cut cleanly and efficiently. Thinner sheets are particularly well-suited for laser cutting, providing precise and smooth edges.

What sets polycarbonate apart is its flame-retardant properties and exceptional impact resistance, making it ideal for industrial and safety applications. It also maintains its structural integrity under extreme conditions, which is why it’s a preferred choice in aerospace and automotive industries.

Acrylic Precision

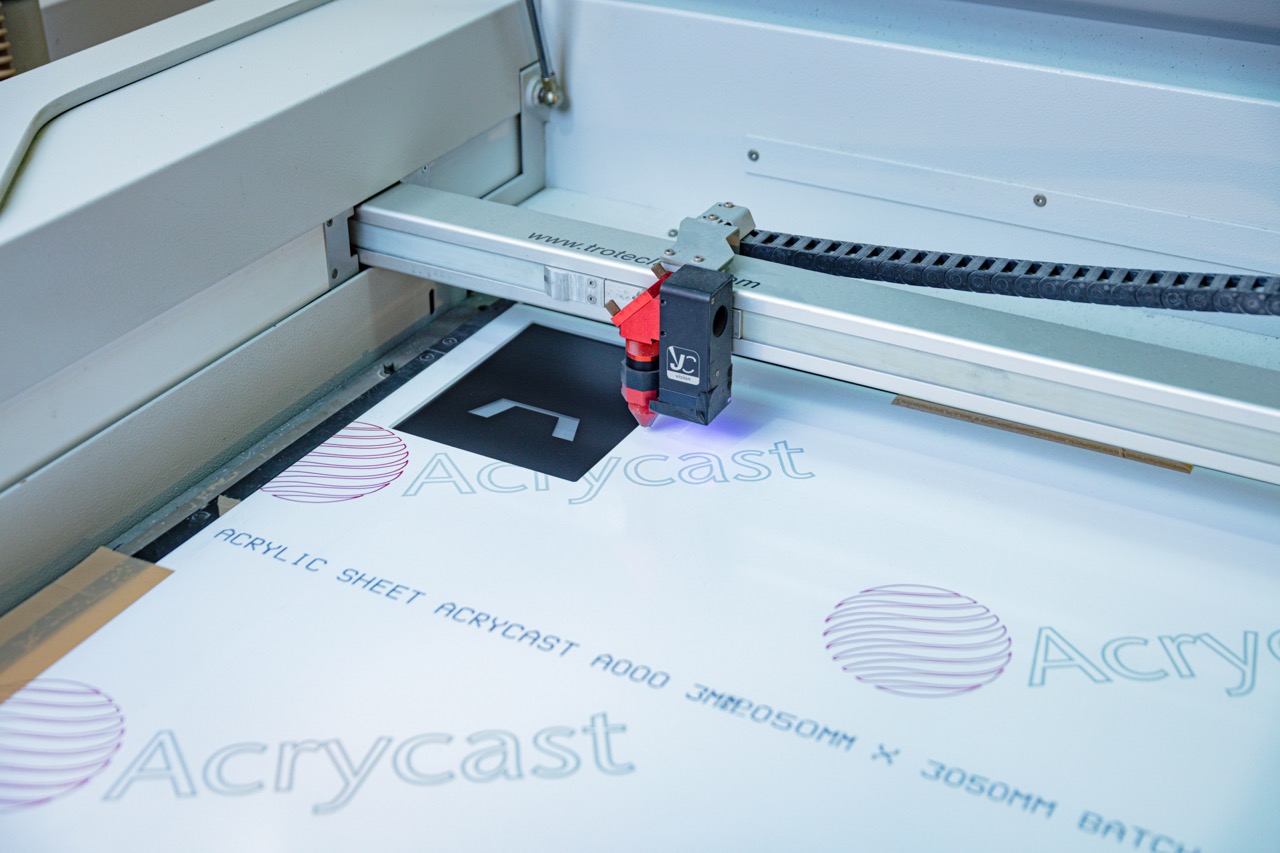

Acrylic, also known as PMMA (Polymethyl Methacrylate), is arguably the most popular material for laser cutting due to its crystal-clear finish and high versatility. It is often used in the creation of signage, display cases, and decorative items. Acrylic’s smooth surface and clarity are unmatched, providing a glass-like appearance without the fragility.

Laser cutting acrylic is highly efficient, producing polished edges directly from the laser process, eliminating the need for additional finishing. Both cast and extruded acrylic are suitable for laser cutting, although cast acrylic tends to produce cleaner cuts with less risk of edge melting.

Acrylic’s ability to come in a wide range of colours and finishes makes it incredibly versatile. Furthermore, it is UV-stable, meaning it won’t yellow or degrade when exposed to sunlight, making it ideal for outdoor applications as well.

Conclusion

When it comes to laser cutting plastic, PETG, Polycarbonate, and Acrylic are undoubtedly the top choices. Each material brings its own strengths—PETG with its durability and flexibility, Polycarbonate with its exceptional toughness, and Acrylic with its clear precision. Choosing the right material depends largely on the specific requirements of your project, but with these three options, you are guaranteed a professional, high-quality finish every time.