Design to Manufacture

Call: 01908 305710

Email: sales@apt123.co.uk

What We do

Design to Manufacture

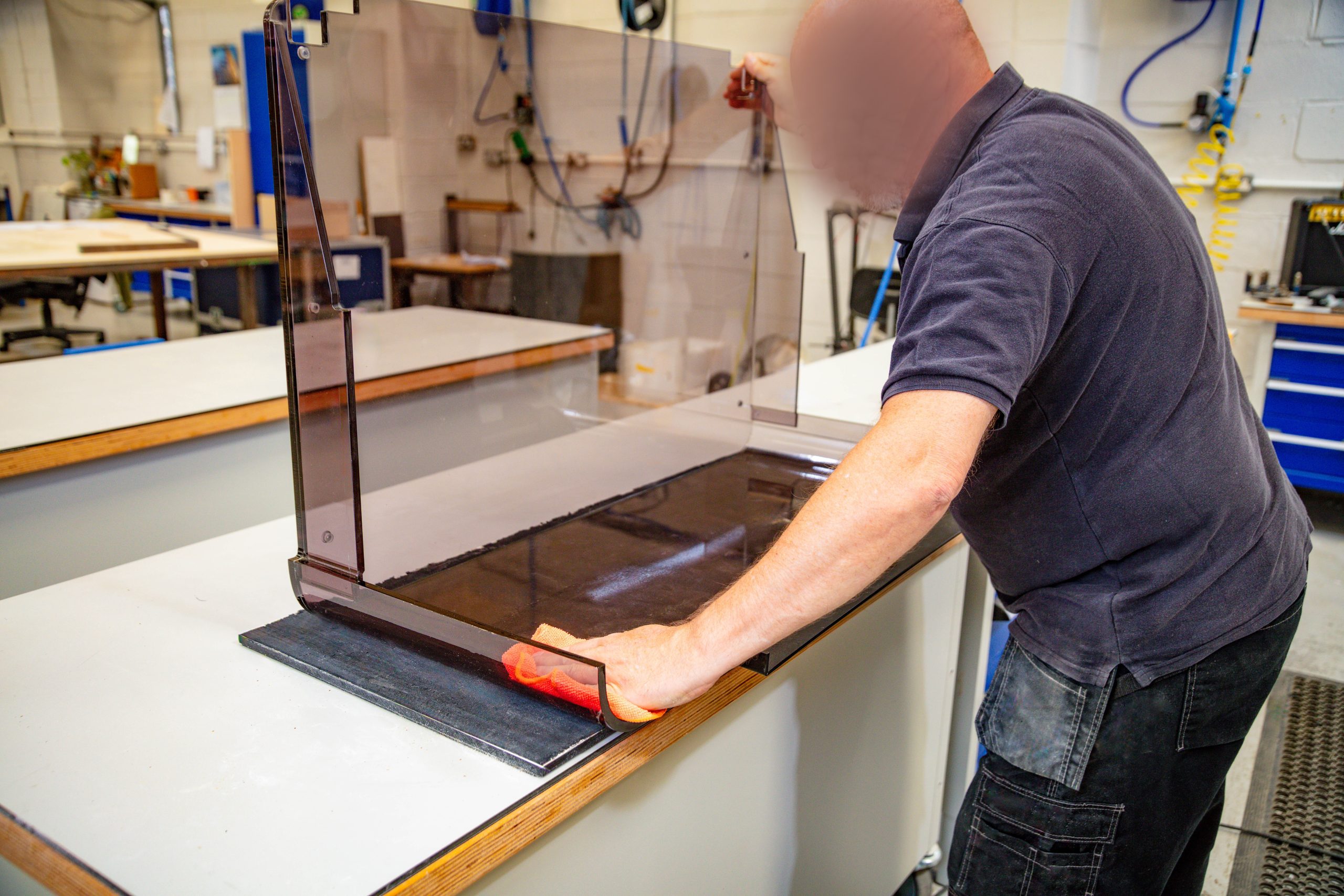

Our team’s aim is to transform your concept into a workable design to enable manufacture of your product.

From Prototype to Reality

We provide answers not questions.

We have in-house Sales Engineers to help you create your product, providing key information to enable you to make a decision on material selection and provide you with any questions you may have on Plastic or processing types.

For drawing solutions we use Solidworks™, Coral Draw™, AutoCAD™ among others and for machining we use Corel, CADCAM™ Etc.

If you need assistance designing your plastic part, we can help you by providing information on manufacturing capabilities for specific features you are trying to achieve or material property’s that your design requires from a particular plastic type.

Our expert staff can help determine the optimal method for producing your part and establish realistic tolerances for building it in plastic.

Our team has been greatly applauded for our continued high standards in helping clients achieve their vision. We are capable of creating a range of specialist bespoke products, from initial prototypes and one offs to full production runs. We can offer clients a one stop shop for new projects, complex assemblies and also solutions to problems with existing products.

What We do

Plastic Components and requirements.

Whatever your requirement we are able to help. We manufacture and supply plastic products at the component, sub-assembly and general assembly levels. Plastic components are straightforward and are the most common item for us.

Assemblies require a higher level of planning and coordination and we are equally as adept at manufacturing these items. When assemblies have non-plastic components we can either source from our own network of component suppliers or source from your nominated supplier. This applies equally to bought-in components like inserts, screws, hinges, handles, interlocks and other off-the-shelf items.

As we work with so many different customers, we are familiar with all phases of product development – from prototype to full production.

We also have controlled processes for implementing Engineering Change Notices.

As our expertise lies in materials and processing technologies, the applications for plastic components we make covers a vast array of items. Our product database exceeds 16,000 items. This means that whatever your requirement, there is a good chance that we have made something similar in the past. Below is a list of the more common item descriptions we see.

However, as the range of items we can supply is vast, all you need to do is send us your sketch or drawing and we will quickly let you know if we are able to help.

Our works orders range from one-offs to the low 1000’s per batch. Most batches we supply are less than 500 units. A number of our customers we supply are build-to-order manufacturers. These companies have MRP systems that order one BOM at a time.

Below is a general list of commonly ordered components, it is not an exhaustive list so if you do not see your requirement please get in touch

Common components we are asked to supply:

Baffles

Bund Bushes

Control Panel Covers

Display Panels

Flanges

Guards

Inserts

Manifolds

Racks

Rollers

Shields

Spacers

Surgical Procedure

Windows

Bezels

Cabinets

Cutting Boards

Door Panels

Freezer Trays

Guide Rails

Insulator Guides

Panels

Rails

Runners

Shims

Star Wheels

Housing

Blocks

Chemical Tanks

Decks

Filler Tubes

Gloves

Hoppers

Lids

Plates

Reservoirs

Scrapers

Slide Rails

Storage Containers

Wall Cladding

Brackets

Chutes

Deflector Diffusers

Filter Plates

Boxes

Housings

Machine Windows

Product Guides

Rings

Screens

Sort Trays

Supports

Wear Strips

A Word on Quality.

Quality and Production control have to go hand in hand, each process of manufacture and inspection is updated constantly with our strategic process recording route card system throughout the manufacturing process, This system managed by our manufacturing scheduling system means our customers can be updated on the progress of their orders where required.

Customer confidence and satisfaction is at the heart of everything we do!

Our other company accreditation include: