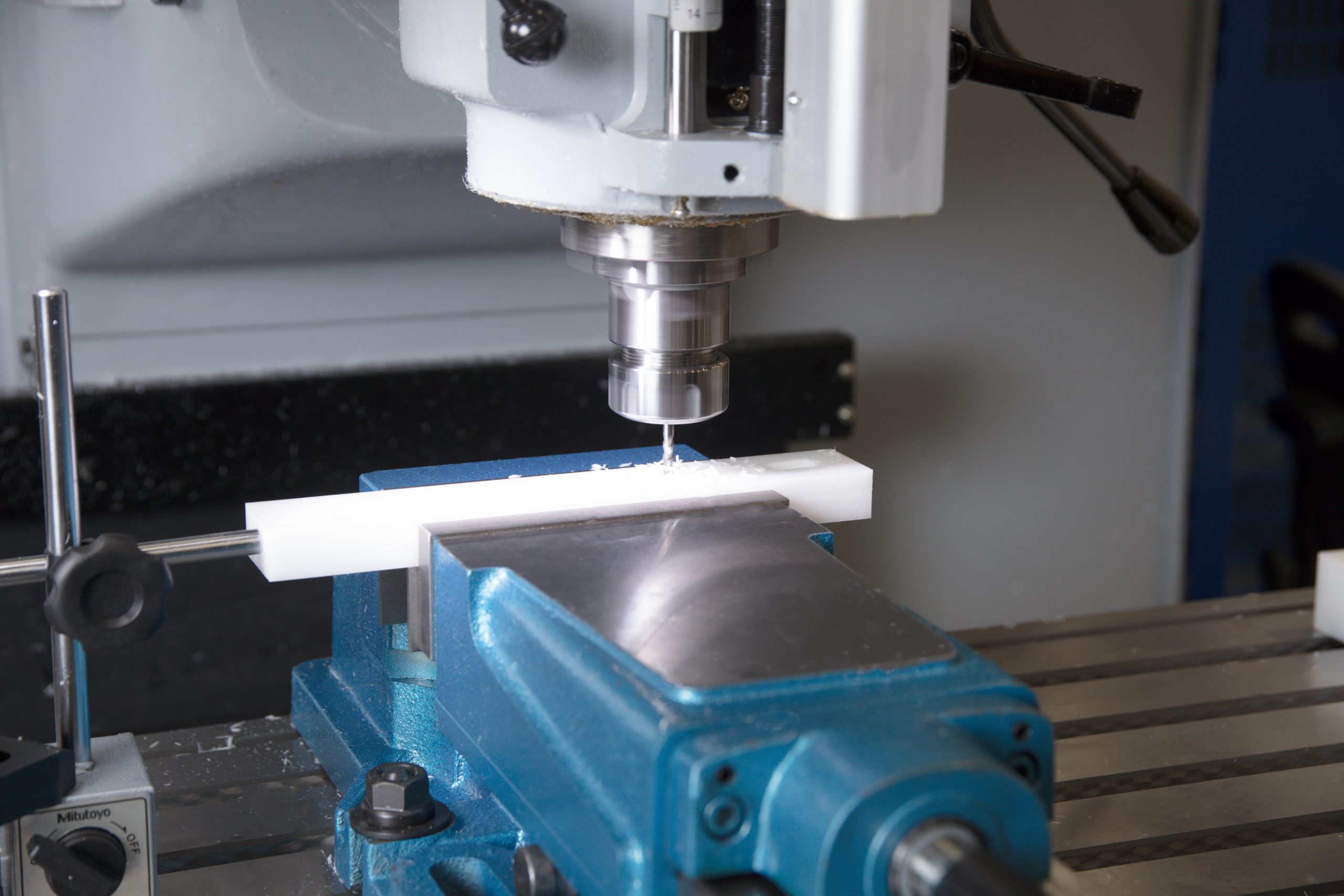

Multi-axis CNC machining

Call: 01908 305710

Email: sales@apt123.co.uk

Unleashing Precision & Versatility: A Glimpse into the World of CNC Routing

Multi-axis CNC machining is a manufacturing process that uses computer-controlled machines to move the cutting tool in multiple directions (four or more) to create complex parts. This process is different from traditional 3-axis CNC machining, which only allows the cutting tool to move in three directions (X, Y, and Z).

Multi-axis CNC machines are typically more complex and expensive than 3-axis machines, but they offer several advantages, including:

- The ability to produce complex parts in a single setup, which can save time and money

- Increased accuracy and repeatability

- Improved surface finishes

- Reduced tool wear

- Increased productivity

Multi-axis CNC machines are used in a wide range of industries, including aerospace, automotive, medical, and electronics. Some common applications include:

- Machining complex aircraft parts, such as turbine blades and engine components

- Manufacturing medical implants and surgical tools

- Producing automotive parts, such as engine blocks and transmission housings

- Creating electronic components, such as circuit boards and semiconductor chips

Types of multi-axis CNC machines

There are two main types of multi-axis CNC machines: simultaneous and positional.

Simultaneous 5-axis machining: This type of multi-axis machining allows the cutting tool to move in all five axes simultaneously. This is the most complex and versatile type of multi-axis machining, and it is capable of producing the most complex parts.

Positional 5-axis machining: This type of multi-axis machining locks the cutting tool in a fixed position (using the rotational axes) and then moves the workpiece in the three linear axes. This is a less complex type of multi-axis machining, but it is still capable of producing complex parts.

Benefits of multi-axis CNC machining

Multi-axis CNC machining offers a number of benefits over traditional 3-axis machining, including:

Reduced setup times: Multi-axis CNC machines can machine complex parts in a single setup, which can save time and money.

Increased accuracy and repeatability: Multi-axis CNC machines are capable of producing parts with high accuracy and repeatability.

Improved surface finishes: Multi-axis CNC machines can produce parts with superior surface finishes.

Reduced tool wear: Multi-axis CNC machines can reduce tool wear by allowing the cutting tool to be used at the optimal angle.

Increased productivity: Multi-axis CNC machines can increase productivity by reducing setup times and machining parts faster.

Requesting a quotation is easy!

Simply upload your files with drawings, 3D-models or sketches in any popular format and we will send your quote within 24 hours.