In modern manufacturing, precision and efficiency are everything. One technology that has revolutionised the way we work with plastic materials is CNC routing. While CNC (Computer Numerical Control) is often associated with wood and metalwork, it’s just as essential in plastic fabrication. But how does it actually work, and why is it such a valuable tool in plastic manufacturing?

What is CNC Routing?

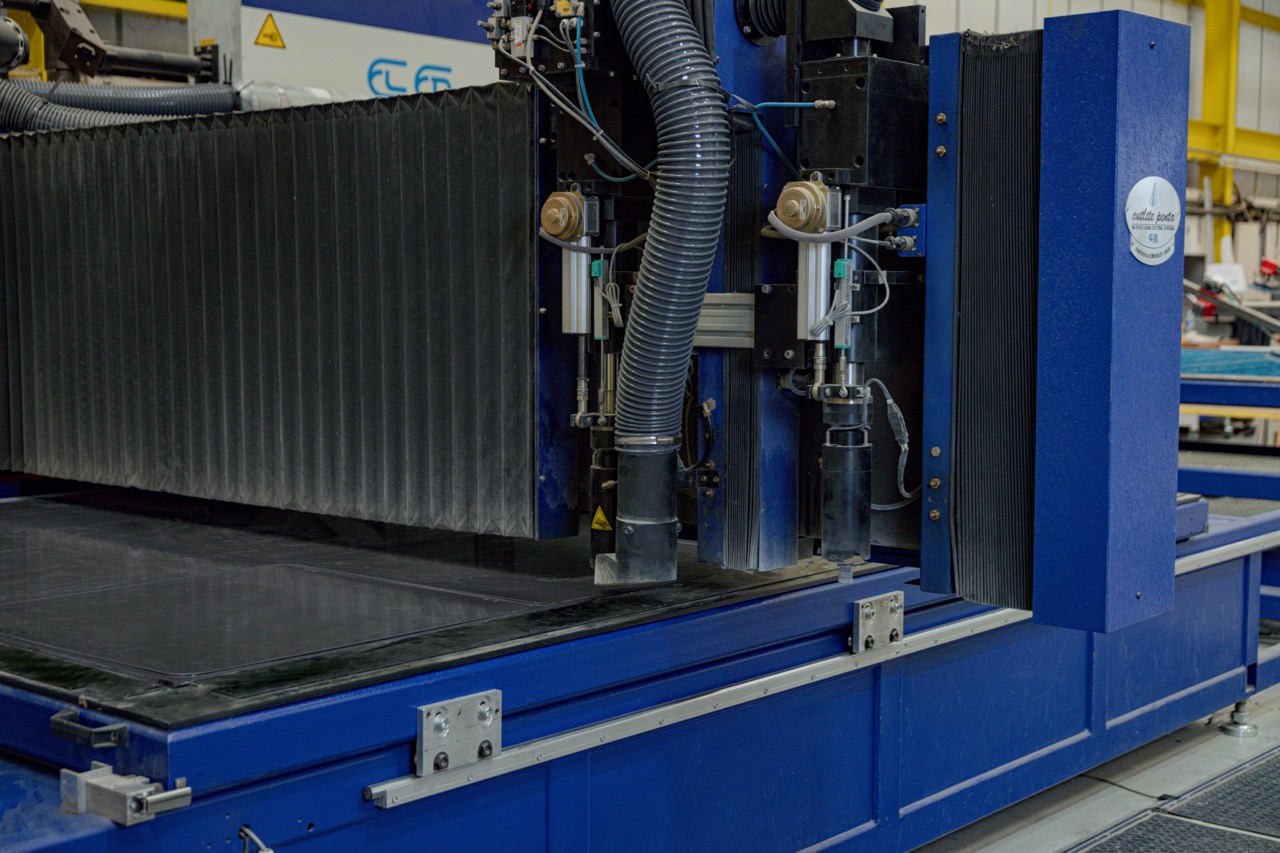

CNC routing is a computer-controlled cutting process that uses a router to remove material from a workpiece based on a digital design. The machine follows pre-programmed instructions, ensuring high accuracy and repeatability. Unlike manual methods, CNC routing significantly reduces the margin for human error, making it ideal for high-volume production and intricate designs.

When it comes to plastic manufacturing, CNC routers are used to cut, drill, engrave, and shape a variety of plastic types, including acrylic, polycarbonate, PVC, HDPE, and more. Whether creating machine parts, signage, or custom enclosures, CNC routing provides a flexible, scalable solution.

The Process of CNC Routing in Plastic Manufacturing

Here’s a step-by-step look at how CNC routing is typically applied in plastic manufacturing:

-

Design and Programming

The process begins with a CAD (Computer-Aided Design) file that outlines the dimensions and shapes required. This design is then converted into a CAM (Computer-Aided Manufacturing) file, which translates the design into machine-readable code, typically G-code. This code controls the router’s movements and functions. -

Material Preparation

A suitable plastic sheet is selected and secured onto the CNC machine’s work surface, usually with a vacuum hold-down system or clamps. Material type, thickness, and quality are carefully considered to match the project specifications. -

Tool Selection

The correct router bit (or cutting tool) is selected based on the material type and desired finish. For plastics, specialised bits are often used to prevent melting, chipping, or burring. These tools are designed to cut cleanly and efficiently without overheating the plastic. -

Routing Operation

Once everything is in place, the machine starts its operation. Guided by the programmed instructions, the router moves in precise paths along the X, Y, and Z axes to cut, drill, or engrave the plastic. The machine maintains consistent speeds and depths, resulting in extremely accurate components. -

Finishing Touches

After routing, the parts may require finishing such as edge smoothing, polishing, or additional fabrication steps. CNC routing often leaves a clean finish, but depending on the material and project, minor post-processing may be necessary.

Benefits of CNC Routing for Plastic

-

High Precision: CNC routers can achieve tight tolerances and intricate detailing that would be difficult or impossible by hand.

-

Efficiency and Speed: Automated routing is much faster than manual methods, especially for repeatable tasks or large production runs.

-

Reduced Waste: The accuracy of CNC routing means less material is wasted during production.

-

Versatility: Compatible with a wide range of plastics and able to perform various operations like drilling, engraving, and contouring.

-

Consistency: Every part produced is virtually identical, which is crucial for applications requiring uniformity.

Common Applications

CNC routing is widely used across different industries where plastic parts are essential. Common applications include:

-

Retail and point-of-sale displays

-

Signage and lettering

-

Industrial machine components

-

Medical device housings

-

Automotive trim parts

-

Electronic enclosures

Conclusion

CNC routing plays a vital role in modern plastic manufacturing, offering a combination of precision, efficiency, and flexibility. Whether you’re producing one-off prototypes or large-scale production runs, this technology allows manufacturers to deliver high-quality plastic components quickly and reliably. As design complexity and demand for custom solutions continue to grow, CNC routing is set to remain a cornerstone of plastic fabrication for years to come.